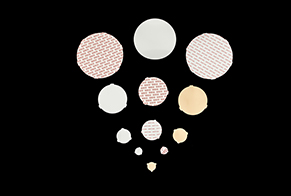

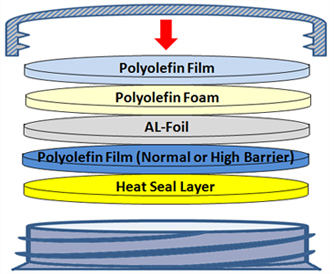

Two-Ply Induction Seal Foam

This integrated induction seal with high frequency induction heating melts the thermal adhesive layer and attaches it to the chamber. Thermal bonding is a reliable protection against oxygen or moisture penetration for contents such as dairy products, beverages, medicines, sauces, spices and many others and preserves their properties for a long time.

Applications

Sealing provides a wide range of products including foods, oils (edible, lubricants), sauces, healthy foods, powdered dry foods, beverages, dairy products, pharmaceuticals and cosmetics and more.

Advantages

- Protection and flooding

- It is easy to peel and flood

- Needs low heat to induce

Types of Containers

PET, PVC, PE, PP, PS, glass, paper cups and ...

- Layer structure may vary depending on the type of container and the contents.

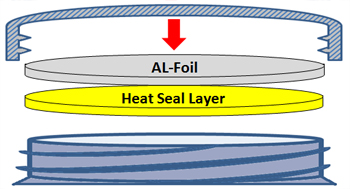

Single layer foil

All layers are composed of only polyolefin film and sealant layer for environment protection and recycling, and further aluminum layer can be constructed according to product characteristics. Used for plastic (PET, PE, PP, PS, etc.), Trays (square or circular), paper cups and bottles. Consumers can see the contents and check them for freshness / contamination..

Applications

Fresh foods (tofu, salads, vegetables, sandwiches, yogurt, etc.), instant food packaging for small businesses.

Advantages

Ensures preservation and hermetic sealing- Easy to check the contents for freshness and contamination.

- Ensures preservation and hermetic sealing.

Types of Containers

PET, PP, PS, PE, Tray (square tray), beverage cups (plastic cups, paper cups, etc.)

- Layer structure may vary depending on the type of container and the contents.

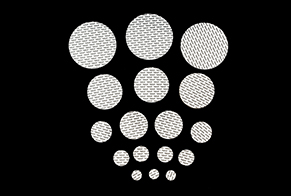

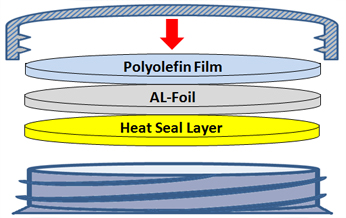

Seal Foil

Applications

Foods (yogurt), medicine, confectionery, cosmetics, etc.

Advantages

- Protects the contents from moisture and contamination.

Types of Containers

PET, HDPE, PP, PS, Glass and ETC.

- Layer structure may vary depending on the type of container and the contents.

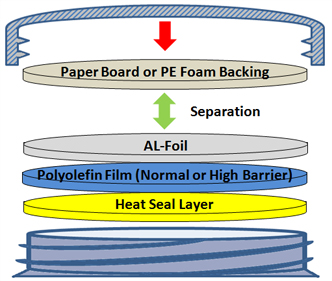

Three-Layer Induction Seal Foam

Ensures maximum sealing composed of two parts which inserted inside the cap and the layer adheres and seals to the opening of the container. Comprises an induction sealing layer and a cardboard or PE foam layer divided by wax; the sealing layer is melted and applied to the opening of the container with aluminum. The strong seal ensures the safety of the consumers and the environment from aggressive filling contents, as well as long-term preservation of product properties. High Barrier layer can be added depending on the acidity of the contents.

Applications

Pesticides/Lubricant/Edible oil, foods, medicine, confectionery, cosmetics and aggressive chemicals

Advantages

- Preserves the freshness/flavor of foods and beverages

- Ensures the safe storage of dangerous substances

Types of Containers

PET, HDPE, PP, (HDPE/EVOH/HDPE) Multilayer containers

- Layer structure may vary depending on the type of container and the contents.

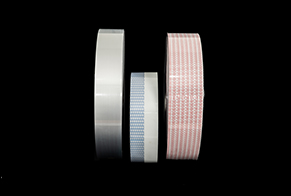

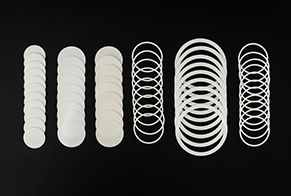

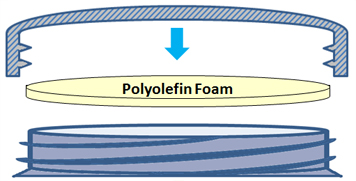

EPE, Polymer Seal

Made from foamed polyethylene, this seal features high elasticity and resilience. Mainly used in screw-type plastic or metal caps. Interacts between the cap and the opening of the container, and seals bottles to prevent leakage and contamination by external substances. This allows effective sealing even when the surface of the container inlet is not flat. Various lamination options (PE, PET, PP, OPP, Saranex, PVDC, PVOH, Tin-plate, etc.) are available to meet the requirements, foam density (Low density, High Density) and thickness can be adjusted. Provided in disc (Pre-cut), O-ring (Donut shape) and tape (Reel/Roll) forms.

Applications

Food, wine, medicine, edible / engine oil, cosmetics, etc.

Advantages

- Prevents leakage of contents.

- Prevents contamination by external substances.

- Effective sealing.

Types of Containers

All plastic containers, glass bottles.

- Layer structure may vary depending on the type of container and the contents.

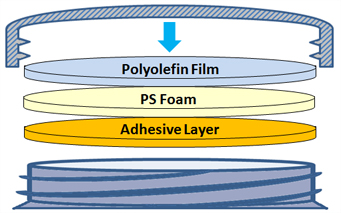

PSP Liner

Seals the opening of the container by the coated wax on the foamed Polystyrene that adheres when pressure is applied by the screw cap even at low temperatures. Widely used for packaging jam, honey, dry, powdered products and pharmaceutical products such as vitamins. Increases the shelf life by preventing leakage and evaporation. Manifests excellent adhesion to glass and plastic containers.

Applications

Pharmaceuticals, dried foods, etc.

Advantages

- Adheres without high-frequency induction sealing machine.

Types of Containers

All plastic containers, glass bottles.

- Layer structure may vary depending on the type of container and the contents.